Z41H Z41Y Flanged Gate Valve ANSI

Description:

Z41H, Z41Y type 150(Lb) ~600(Lb)flanged gate valveANSI includes manually operated, flanged connection, rod wedge rigid single-gate valve gate valve ANSI. The material of the seat sealing surface is hard alloy, its pressure level ranges from 150 Lb to 600 (Lb). The valve body is made of carbon steel, Z41Y- 150 (Lb) ~600 (Lb), chromium molybdenum steel Z41Y-300(Lb) I, Z41Y-400 (Lb) I, stainless steel Z41Y-150 (Lb) P~600 (Lb) P, Z41Y-150 (Lb) R~600 (Lb) R, Z41H-600 (Lb) P and Z41H-600 (Lb) R) of the American standard gate valve

Performances and Parameters

|

Z41H, Z41Y-150Lb~600Lb |

| Type |

Pressure Level(Lb) |

Applicable Temperature/°C |

Applicable medium |

| Z41Y-150(Lb) |

150 |

≤425 |

Water, Steam, Oil |

| Z41Y-150(Lb)P |

150 |

≤200 |

Corrosive Medium |

| Z41Y-150(Lb)R |

| Z41Y-300(Lb) |

300 |

≤425 |

Water, Steam, Oil |

| Z41Y-300(Lb)P |

300 |

≤200 |

Corrosive Medium |

| Z41Y-300(Lb)R |

| Z41Y-400(Lb) |

400 |

≤425 |

Water, Steam, Oil |

| Z41Y-600(Lb) |

600 |

| Z41H-150(Lb) |

150 |

≤425 |

Water, Steam, Oil |

| Z41H-300(Lb) |

300 |

| Z41H-400(Lb) |

400 |

| Z41Y-300(Lb)I |

300 |

≤550 |

Water, Steam, Oil |

| Z41Y-400(Lb)I |

400 |

≤450 |

Non-corrosive Medium |

| Z4Y-400(Lb)P |

400 |

≤150 |

Less Corrosive Medium |

| Z41Y-400(Lb)R |

≤200 |

Corrosive Medium |

| Z41H-600(Lb) |

600 |

≤200 |

Non-corrosive Medium |

| Z41H-600(Lb)I |

≤350 |

| Z41H-600(Lb)P |

≤200 |

Corrosive Medium |

| Z41Y-600(Lb)R |

600 |

≤150 |

Corrosive Medium |

Material for Main Parts

|

Z41H, Z41Y -150(Lb)~600(Lb) |

| Type |

Material |

| Valve Body , Deck and Gate |

Valve Rod |

Sealing Surface |

Fillings |

| Z41Y-150(Lb) |

Carbon Steel |

Chromium Stainless Steel |

Hominess Alloy Surfacing |

Asbestos, Graphite or Flexible Graphite |

| Z41Y-150(Lb)P |

Chromated Nickel Titanium Steel |

Ci Ni Steel |

— |

— |

| Z41Y-150(Lb)R |

Ci Ni Mo Ti Steel |

Cr. Ni .Mo .Ti steel |

— |

— |

| Z41Y-300(Lb) |

Carbon Steel |

Chromium Stainless Steel |

Hominess Alloy Surfacing |

Asbestos, Graphite or Flexible Graphite |

| Z41Y-300(Lb)P |

Ci Ni Steel |

Ci Ni Steel |

— |

— |

| Z41Y-300(Lb)R |

Ci Ni Mo Ti Steel |

Ci Ni Mo Ti Steel |

— |

— |

| Z41Y-400(Lb) |

Carbon Steel |

Chromium Stainless Steel |

Hominess Alloy Surfacing |

Asbestos, Graphite or Flexible Graphite |

| Z41Y-600(Lb) |

| Z41H-150(Lb) |

Carbon Steel |

Chromium Stainless Steel |

Chromium Stainless Steel |

Asbestos, Graphite or Flexible Graphite |

| Z41H-300(Lb) |

| Z41H-400(Lb) |

| Z41Y-300(Lb)I |

Chromium-molybdenum Steel |

Chromium Stainless Steel |

Hominess Alloy Surfacing |

Asbestos, Graphite or Flexible Graphite |

| Z41Y-400(Lb)I |

Chromium-molybdenum Steel |

Chromium-Molybdenum Steel, CoCrW |

— |

— |

| Z4Y-400(Lb)P |

Chromium Nickel Titanium Stainless Steel |

Chromium Nickel Titanium Stainless Steel |

Hominess Alloy Surfacing |

Asbestos Measurements or Flexible Graphite |

| Z41Y-400(Lb)R |

Ci Ni Mo Ti Steel |

Ci Ni Mo Ti Steel, CoCrW |

— |

— |

| Z41H-600(Lb) |

Carbon Steel |

Chromium Steel |

— |

— |

| Z41H-600(Lb)I |

| Z41H-600(Lb)P |

Ci Ni Steel |

Chrome Molybdenum Vanadium Steel |

| Z41Y-600(Lb)R |

Chromium Nickel Molybdenum Titanium Stainless Steel |

Chromium Nickel Molybdenum Titanium Stainless Steel |

Hominess Alloy Surfacing |

Asbestos, Graphite or Flexible Graphite |

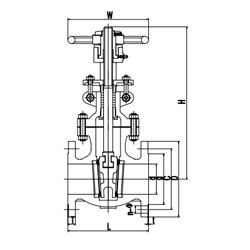

Configuration, Structure and Size (mm)

|

Z41H, Z41Y- 150(Lb) |

| DN |

DN/in |

L |

D |

D1 |

D2 |

b |

z×Φd |

H≈ |

D0≈ |

Weight/kg |

| 50 |

2 |

178 |

152 |

120.5 |

120.5 |

16 |

4×Φ19 |

323 |

200 |

23 |

| 65 |

21/2 |

190 |

178 |

139.5 |

139.5 |

18 |

4×Φ19 |

347 |

250 |

32 |

| 80 |

3 |

203 |

190 |

152.5 |

152.5 |

19 |

4×Φ19 |

383 |

250 |

40 |

| 100 |

4 |

229 |

229 |

190.5 |

190.5 |

24 |

8×Φ19 |

457 |

300 |

63 |

| 125 |

5 |

254 |

254 |

216 |

216 |

24 |

8×Φ22 |

632 |

300 |

66 |

| 150 |

6 |

267 |

279 |

241.5 |

241.5 |

26 |

8×Φ22 |

635 |

350 |

108 |

| 200 |

8 |

292 |

343 |

298.5 |

298.5 |

29 |

8×Φ22 |

762 |

350 |

181 |

| 250 |

10 |

330 |

406 |

362 |

362 |

31 |

12×Φ25 |

895 |

400 |

263 |

| 300 |

12 |

356 |

483 |

432 |

432 |

32 |

12×Φ25 |

1080 |

500 |

346 |

| 350 |

14 |

381 |

533 |

476 |

476 |

35 |

12×Φ29 |

1295 |

600 |

488 |

| 400 |

16 |

406 |

579 |

540 |

540 |

37 |

16×Φ29 |

1435 |

600 |

621 |

| 450 |

18 |

432 |

635 |

578 |

578 |

40 |

16×Φ32 |

1626 |

650 |

814 |

| 500 |

20 |

457 |

698 |

635 |

635 |

43 |

20×Φ32 |

1829 |

650 |

992 |

| 600 |

24 |

508 |

813 |

749.5 |

749.5 |

48 |

20×Φ35 |

2175 |

700 |

1492 |

| 750 |

30 |

610 |

984 |

914.5 |

914 |

75 |

28×Φ35 |

2692 |

700 |

2272 |

| Z41H, Z41Y -300(Lb) |

| DN |

DN/in |

L |

D |

D1 |

D2 |

B |

z×Φd |

H≈ |

D0≈ |

Weight/kg |

| 50 |

2 |

216 |

165 |

127 |

92 |

16 |

4×Φ19 |

323 |

200 |

23 |

| 65 |

21/2 |

241 |

190 |

149 |

105 |

18 |

4×Φ19 |

347 |

250 |

32 |

| 80 |

3 |

283 |

210 |

168.5 |

127 |

19 |

4×Φ19 |

383 |

250 |

40 |

| 100 |

4 |

305 |

254 |

200 |

157 |

24 |

8×Φ19 |

457 |

300 |

63 |

| 125 |

5 |

381 |

279 |

235 |

186 |

24 |

8×Φ22 |

632 |

300 |

66 |

| 150 |

6 |

403 |

318 |

270 |

216 |

26 |

8×Φ22 |

635 |

350 |

108 |

| 200 |

8 |

419 |

381 |

330 |

270 |

29 |

8×Φ22 |

762 |

350 |

171 |

| 250 |

10 |

457 |

444 |

387.5 |

324 |

31 |

12×Φ25 |

895 |

400 |

263 |

| 300 |

12 |

502 |

521 |

451 |

381 |

32 |

12×Φ25 |

1080 |

500 |

346 |

| 350 |

14 |

762 |

584 |

514.5 |

413 |

35 |

12×Φ29 |

1295 |

600 |

488 |

| 400 |

16 |

838 |

648 |

571.5 |

470 |

37 |

16×Φ29 |

1435 |

600 |

621 |

| 450 |

18 |

914 |

711 |

628.5 |

533 |

40 |

16×Φ32 |

1626 |

650 |

814 |

| 500 |

20 |

991 |

775 |

686 |

584 |

43 |

20×Φ32 |

1829 |

650 |

992 |

| 600 |

24 |

1143 |

914 |

813 |

692 |

48 |

20×Φ35 |

2175 |

700 |

1492 |

|

Z41H-Z41Y- 400(Lb) |

| DN |

DN/in |

L |

D |

D1 |

D2 |

b |

z×Φd |

H≈ |

D0≈ |

Weight/kg |

| 50 |

2 |

292 |

465 |

127 |

92 |

25 |

8×Φ19 |

368 |

250 |

35 |

| 65 |

2½ |

330 |

190 |

149.4 |

105 |

29 |

8×Φ22 |

394 |

300 |

47 |

| 80 |

3 |

356 |

210 |

168.1 |

127 |

32 |

8×Φ22 |

473 |

3003 |

65 |

| 100 |

4 |

406 |

254 |

200.2 |

157 |

35 |

8×Φ25 |

622 |

50 |

90 |

| 125 |

5 |

457 |

279 |

235 |

186 |

36 |

8×Φ25 |

686 |

400 |

153 |

| 150 |

6 |

495 |

318 |

269.7 |

216 |

41 |

12×Φ25 |

750 |

400 |

260 |

| 200 |

8 |

597 |

381 |

330.2 |

270 |

48 |

12×Φ29 |

876 |

500 |

390 |

| 250 |

10 |

673 |

444 |

387.4 |

324 |

54 |

16×Φ32 |

1041 |

600 |

535 |

| 300 |

12 |

762 |

521 |

450.8 |

381 |

57 |

16×Φ35 |

1181 |

650 |

886 |

| 350 |

14 |

826 |

584 |

514.4 |

413 |

60 |

20×Φ35 |

1588 |

700 |

960 |

| 400 |

16 |

902 |

648 |

571.5 |

470 |

64 |

20×Φ38 |

1803 |

700 |

1424 |

| Z41H, Z41Y- 600(Lb) |

| DN |

DN/in |

L |

D |

D1 |

D2 |

b |

z×Φd |

H≈ |

D0≈ |

Weight/kg |

| 50 |

2 |

292 |

165 |

127 |

92 |

33 |

8×Φ19 |

510 |

254 |

44 |

| 65 |

2½ |

330 |

190 |

149 |

100 |

36 |

8×Φ22 |

554 |

254 |

60 |

| 80 |

3 |

356 |

210 |

168 |

127 |

39 |

8×Φ22 |

595 |

305 |

80 |

| 100 |

4 |

432 |

273 |

216 |

157 |

45 |

8×Φ25 |

712 |

356 |

145 |

| 125 |

5 |

508 |

330 |

266.5 |

186 |

52 |

8×Φ29 |

826 |

406 |

236 |

| 150 |

6 |

559 |

356 |

292 |

216 |

55 |

12×Φ29 |

995 |

508 |

309 |

| 200 |

8 |

660 |

419 |

349 |

270 |

63 |

12×Φ32 |

1157 |

610 |

522 |

| 250 |

10 |

787 |

508 |

432 |

324 |

71 |

16×Φ35 |

1373 |

686 |

779 |

| 300 |

12 |

838 |

559 |

489 |

381 |

74 |

20×Φ35 |

1603 |

686 |

1108 |

| 350 |

14 |

889 |

603 |

527 |

413 |

77 |

20×Φ38 |

1930 |

762 |

1506 |

| 400 |

16 |

991 |

686 |

603 |

470 |

84 |

20×Φ41 |

2032 |

889 |

1939 |

Sketch of External Form and Connection Dimension:

Statement: this information is just for reference, for detailed information, please contact us.