Feature:

The valve cover connection of H61H, H61Y, 800 (Lb) socket welded forged steel check valve has three design forms. The first is a bolt -type bonnet. The body and cover of this kind of valve are connected with nut. It can also be connected with metal ring joint if customers have special requirements. The second design form of socket welded forged steel check valve is welding-type bonnet. The valve which is designed according to this form adopts threaded connections between the body and bonnet. It employs the welding sealing. It can also adopt the welding sealing if you have special needs. The third type of socket welded forged steel check valve is the pressure self-tight bonnet. The body and bonnet of this kind of valve uses threaded connections. It adopts internal pressure ring seal.

Standard of Socket Welded Forged Steel Check Valve:

Design and manufacture: MSSP-118, ASME B16.34

Test: API 598

Mark: MSS-SP-25

Performance of Socket Welded Forged Steel Check Valve:

| Model | H61H | H61Y | |

| Suitable temperature (℃) | ≤425 | ||

| Suitable medium | Water, steam, oil products; | ||

| Materials | Body, valve cover | Carbon steel | |

| Valve clack | Chromium stainless steel | ||

| Seal surface | Chromium stainless steel or carbon steel butt welding iron-base alloy | ||

| Gasket | Flexible graphite | ||

Main External and Connecting Dimensions of Socket Welded Forged Steel Check Valve:

| Nominal pressure (DN) | Size (mm) | Weight (kg) | |||||

| mm | in | L | l | D | D1 | H | |

| 15 | 1/2 | 80 | 10 | 34 | 21.8 | 47.5 | 1.25 |

| 20 | 3/4 | 90 | 13 | 40 | 27.1 | 52.5 | 1.6 |

| 25 | 1 | 100 | 13 | 50 | 33.8 | 62.5 | 2.4 |

| 32 | 1 1/4 | 120 | 13 | 58 | 42.6 | 78 | 3.75 |

| 40 | 1 1/4 | 140 | 13 | 66 | 48.7 | 92 | 5.5 |

| 50 | 2 | ||||||

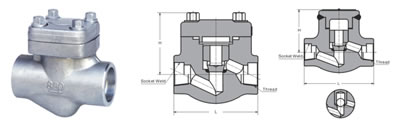

Structure Demonstrate of Socket Welded Forged Steel Check Valve:

Statement: this information is just for reference, for detailed information, please contact us.