Description:

The models of this kind of valve include H41H, H41Y, H41W, etc. The diameter range will be DN15-DN50 and the working pressure will be 900Lb-1500Lb. This check valve is made of forged steel. H41H, H41Y, H41W forged steel flange check valve can open and close automatically on the force from the flow of medium. This valve can also be called reflux valve, non-return valve, one-way valve or counterbalance valve. It is an automatic valve whose main functions are to prevent the backflow of medium, the reverse of pump and its driving and the leakage of the medium in the containers. This check valve can also be applied to the pipeline whose pressure may surpass the system pressure. This forged steel flange check valve can be divided into swing check valve and lift check valve. The swing check valve will rotate depend on the gravity. And the lift check valve will move along the axis.

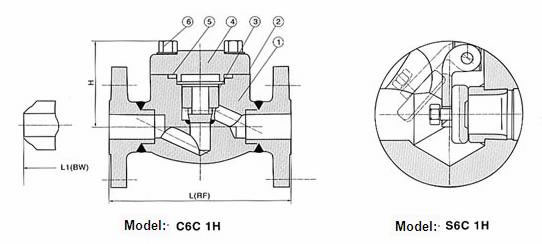

Forged Steel Flange Check Valve: 150Lb-600Lb

Standard Material List of Forged Steel Flange Check Valve: 150Lb-600Lb

| No. | Part | CS to ASTM | AS to ASTM | SS to ASTM | |

| Type A105N | Type F22 | Type F304(L) | Type F316(L) | ||

| 1 | Body | A105N | A182 F22 | A182 F304(L) | A182 F316(L) |

| 2 | Plate | SS | |||

| 3 | Valve clack | A276 420 | A276 304 | A276 304(L) | A276 316(L) |

| 4 | Valve deck | A105N | A182 F22 | A182 F304(L) | A182 F316(L) |

| 5 | Gasket | 316 & Flexible graphite | 316 & PTFE | ||

| 6 | Bolt | A193 B7 | A193 B16 | A193 B8(M) | A193 B8(M) |

| Suitable medium | Water, steam, oil products, etc. | Water, steam, oil products, etc. | Nitric acid acetic acid, etc. | ||

| Suitable temperature | -29°C~425°C | -29°C~550°C | -29°C~200°C | ||

Note: According to the customer's requirements, other materials of self sealing swing check valve also can be used. Seal face material will be selected by the customer.

CS = carbon steel; AS = alloy steel; SS = stainless steel;

Size (mm) and Weight (Kg) of Forged Steel Flange Check Valve:150Lb-600Lb

| NPS | 1/2 | 3/4 | 1 | 11/4 | 11/2 | 2 | ||

| L(RTJ) L1(BW) |

150 | 108 | 117 | 127 | 140 | 165 | 203 | |

| 300 | 152 | 178 | 203 | 216 | 229 | 267 | ||

| 600 | 165 | 190 | 216 | 229 | 241 | 292 | ||

| H | 150,300 | 61 | 61 | 79 | 95 | 103 | 118 | |

| 600 | 61 | 79 | 95 | 103 | 118 | 135 | ||

| Weight | 150 | RTJ | 2.56 | 3.37 | 4.37 | 8.17 | 8.94 | 12.64 |

| BW | 1.70 | 1.90 | 2.10 | 5.12 | 5.50 | 7.89 | ||

| 300 | RTJ | 2.73 | 3.65 | 4.74 | 8.77 | 9.60 | 13.70 | |

| BW | 1.90 | 2.10 | 3.00 | 5.12 | 6.60 | 7.85 | ||

| 600 | RTJ | 3.00 | 4.00 | 5.83 | 9.47 | 10.10 | 15.6 | |

| BW | 2.00 | 3.12 | 4.25 | 7.25 | 8.56 | 13.60 | ||

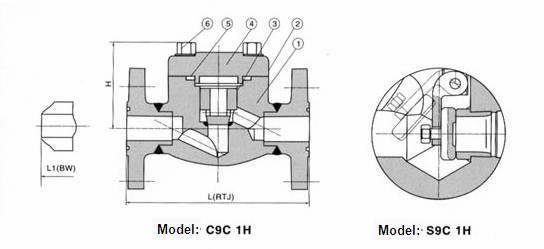

Forged Steel Flange Check Valve: 900Lb-1500Lb

Standard Material List of Forged Steel Flange Check Valve: 900Lb-1500Lb

| No. | Part | CS to ASTM | AS to ASTM | SS to ASTM | |

| Type A105N | Type F22 | Type F304(L) | Type F316(L) | ||

| 1 | Body | A105N | A182 F22 | A182 F304(L) | A182 F316(L) |

| 2 | Plate | SS | |||

| 3 | Valve clack | A276 420 | A276 304 | A276 304(L) | A276 316(L) |

| 4 | Valve deck | A105N | A182 F22 | A182 F304(L) | A182 F316(L) |

| 5 | Gasket | 316 & Flexible graphite | 316 & PTFE | ||

| 6 | Bolt | A193 B7 | A193 B16 | A193 B8(M) | A193 B8(M) |

| Suitable medium | Water, steam, oil products, etc. | Water, steam, oil products, etc. | Nitric acid acetic acid, etc. | ||

| Suitable temperature | -29°C~425°C | -29°C~550°C | -29°C~200°C | ||

Note: According to the customer's requirements, other materials of self sealing swing check valve also can be used. Seal face material will be selected by the customer.

CS = carbon steel; AS = alloy steel; SS = stainless steel;

Size (mm) and Weight (Kg) of Forged Steel Flange Check Valve:900Lb-1500Lb

| NPS | 1/2 | 3/4 | 1 | 11/4 | 11/2 | 2 | |

| L(RTJ) | 216 | 229 | 254 | 279 | 305 | 371 | |

| L1(BW) | 216 | 229 | 254 | 279 | 305 | 368 | |

| H | 79 | 79 | 95 | 104 | 120 | 139 | |

| Weight | RTJ | 8.5 | 10.5 | 15.7 | 20.8 | 27.2 | 33.0 |

| BW | 6.4 | 8.0 | 13.2 | 17.8 | 24.2 | 29.7 | |

Statement: this information is just for reference, for detailed information, please contact us.