Description:

The pressure of this globe valve is Class 800LB. F304, F316, F304L, F316L, LF2, F11, F22, F5 are available for valve body materials. The construction of this product has various features. For example, bolted bonnet or welded bonnet will be adopted. It also has threaded end or socket welding end. This forged steel globe valve has a rising stem and an integral HF seat, etc.

Design & Testing International Standard:

Threaded end: ASME B1.20.1

Socket welding end: ASME B16.11

Basic design: API602, BS 5352

Inspection and test: API598

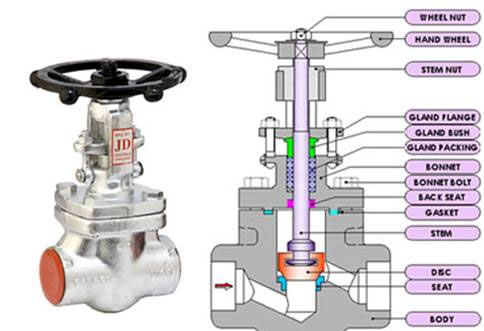

Parts List of Forged Steel Globe Valve:

| NO. | PART | MATERIALS |

| 1 | Body | ASTM A105N/Stellite Overly |

| 2 | Disc | ASTM A276 420 |

| 3 | Stem | ASTM A276 410 |

| 4 | Gasket | 304SS Spiral Wound W/Graphite |

| 5 | Bolt | ASTM A193 Gr.B7 |

| 6 | Eye Pin | ASTM A276 410 |

| 7 | Gland Flange | ASTM A105N |

| 8 | Eyebolt Nut | ASTM A194 Gr.2H |

| 9 | Eyebolt | ASTM A276 410 |

| 10 | Bonnet | ASTM A105N |

| 11 | Handwheel | Malleable lron |

| 12 | H.W.Lock Nut | ASTM A108 1020 |

| 13 | Washer | ASTM A276 420 |

| 14 | Nameplate | Aluminum |

| 15 | Stem Nut | Aluminum Bronze |

| 16 | Gland | ASTM A276 410 |

| 17 | Packing | Graphite |

Pictures of Forged Steel Globe Valve:

Dimensions & Weights of Forged Steel Globe Valve:

| SIZE(IN.) | DIM.(MM) | WT.(KG) | |||||

| CONV. | STD. | d | L | H | D | BB | WB |

| 1/2 | 3/8 | 10.0 | 111 | 207 | 180 | 3.7 | 3.4 |

| 3/4 | 1/2 | 13.0 | 111 | 207 | 180 | 3.6 | 3.3 |

| 1 | 3/4 | 17.0 | 120 | 240 | 180 | 6.8 | 6.0 |

| 1 1/4 | 1 | 23.0 | 152 | 258 | 200 | 7.6 | 5.6 |

| 1 1/2 | 1 1/4 | 30.0 | 172 | 330 | 250 | 11.6 | 10.3 |

| 2 | 1 1/2 | 38.0 | 200 | 355 | 300 | 15.0 | 14.2 |

Statement: this information is just for reference, for detailed information, please contact us.